This product has limited availability. Some accessories, replacement parts, or services may still be available when it is no longer available.

Visão Geral

For turf grass water management applications, Campbell Scientific’s T.Weather T107 station and Toro’s Central Irrigation and Control System automatically monitor meteorological conditions that affect turf grass water consumption. This information is used by the Central Irrigation System to analyze current irrigation requirements.

Leia maisimagens

3D / CAD Files:

Descrição Técnica

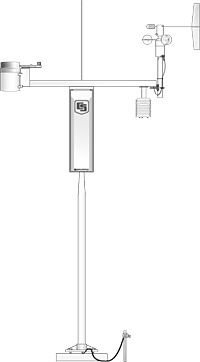

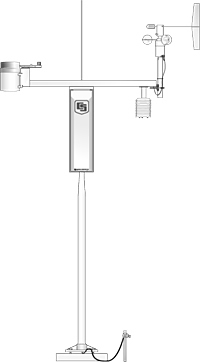

Our T107 station consists of meteorological sensors, an aluminum 3-m pole, and an environmental enclosure that houses a CR1000M module and a 7-Ahr sealed rechargeable battery. The battery is recharged via ac power or a 10-W solar panel. Sealed circular connectors are provided on the outside of the enclosure to simplify sensor hookup.

Meteorological sensors included with the T107 are the CS305-ET Solar Radiation Sensor, HMP60-ETS Air Temperature and Relative Humidity Probe, TE525-ET Tipping Bucket Rain Gage, and either the 034B-ETM Wind Set or WindSonic1-ETM 2-D Sonic Wind Sensor.

Phone or short haul modems are used to transfer hourly weather data between the weather station and a central computer. The central computer calculates ETo and programs each controlling satellite with the appropriate irrigation cycles.

Especificações

| -NOTE- |

The T107 has components that have their own specifications. To review these specifications, refer to the appropriate products below: |

Documentos Relacionados

Lâminas do produto

Conformidade

Compatibilidade

Replacement sensors for the T107 have a -ET or -ETM suffix.

Perguntas Frequentes Relacionadas

Number of FAQs related to T107: 4

Expandir todosRecolher todos

-

Yes, but the following conditions must be met:

- The station has to use IP communications (through an Ethernet, Wi-Fi, or cellular modem connection).

- The programming on the weather station’s data logger has to be changed to produce the data in the appropriate format and communicate the data to the Weather Underground website.

-

If VisualWeather is used with the ET107, T107 (Toro), ET106, or MetData1, and the station has a standard configuration, setting up the station in VisualWeather is relatively simple. Select the station from the list in the Weather Station Network screen, and most of the work is automatically performed.

If, however, a custom station, a different station model, or a different variation for one of the sensors is used, it is necessary to set up a custom station in the Weather Station Network setup screens. In the Station Selection screen, select Custom.

Follow the screens that ask about the details of the station. Then, VisualWeather will connect to the station and get the names and fields of the data tables on the station where the data is stored. Because the names and fields of these tables are meaningless to VisualWeather, a mapping process must be used to map data table fields to fields and units that VisualWeather recognizes. This mapping allows VisualWeather to create screens and reports that are meaningful.

Because the data tables are often identified with a number and the fields are often cryptic, the mapping process can sometimes be confusing. To map fields for a custom station, contact Campbell Scientific for assistance.

-

To post data on a website, the data from the station needs to be regularly collected and put into a viewable format. Campbell Scientific offers two software options that can perform scheduled data collection: LoggerNet and VisualWeather.

VisualWeather is a simple solution that can be used either to connect to the station and monitor data or to set up scheduled data collection. VisualWeather also has powerful reporting capabilities that can be automated. If desired, the screens and reports can be transferred via FTP to a user’s website. A sample site is available for viewing. Using a mouse, hover over the Logan_Utah field in the upper left corner of the web page to view the reports we have selected to generate.

LoggerNet can also be used either to connect to the station and monitor data or to set up scheduled data collection. LoggerNet has more power and flexibility than VisualWeather, but it requires more time and knowledge to implement. For example, LoggerNet comes with an RTMC development tool to create a screen similar to the one in VisualWeather and display the data, but LoggerNet requires that the user learn how to use the RTMC software. In addition, LoggerNet has the ability to transfer data via FTP, but the transfer needs to be set up as a task and then scheduled with the LoggerNet Task Manager.

-

Campbell Scientific recommends the following maintenance schedule:

- Once a week: check the rain gage funnel, and clean as necessary.

- Once a month: check the solar radiation sensor, and clean as necessary.

- Every 3 months: clean the temperature/RH radiation shield.

- Every 6 months to 1 year: replace the two desiccant packs (pn 4905).

- Every 1 to 3 years: have Campbell Scientific replace the wind speed bearings and reed switch. Request a return material authorization (RMA) number by following the steps listed on our Repair and Calibration page.

- Every 1 to 3 years: replace the relative humidity chip (pn 9598).

- Once every 3 years: have Campbell Scientific calibrate the solar radiation sensor. Request a return material authorization (RMA) number by following the steps listed on our Repair and Calibration page.

- Once every 5 years: have Campbell Scientific calibrate the rain gage sensor. Request a return material authorization (RMA) number by following the steps listed on our Repair and Calibration page.

- Once every 5 years: have Campbell Scientific calibrate the data logger. Request a return material authorization (RMA) number by following the steps listed on our Repair and Calibration page.