How to Get Accurate Vibrating Wire Measurements with Long Cable Lengths

de Nathanael Wright | Atualizada: 10/17/2023 | Comentários: 0

Typically, when you use long cable lengths for your vibrating wire measurements, you experience a weaker signal with a greater chance of interference. So, how do you overcome this challenge and improve your measurement quality? Keep reading to find out.

At Campbell Scientific, our vibrating wire measurement hardware uses our patented VSPECT® technology to offer a distinct advantage over other vibrating wire measurement systems on the market. In addition to its ability to filter out interference, the pinpoint accuracy of VSPECT allows our monitoring platforms to perform vibrating wire measurements over extremely long cable lengths.

Conducting a Demonstration

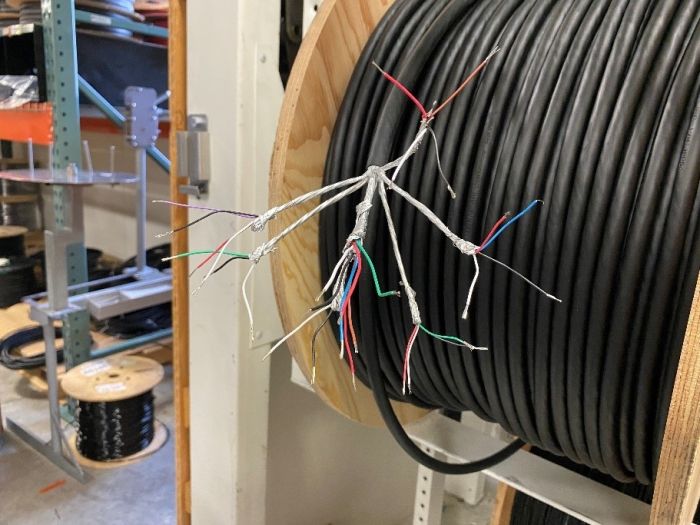

We decided to test this measurement claim by conducting a demonstration using long cable lengths. We took a long spool of cable and carefully connected the ends, extending our cable to a length of 4.2 km (2.61 mi). Then we used alligator clips to connect a vibrating wire piezometer to the exposed wires on one end of the spool and a VWAnalyzer Vibrating Wire Analzyer to the other end of the spool.

We then took a series of measurements over the long cable length using the handheld VWAnalzyer.

Introducing Interference

After successfully taking the measurement reading over the 4.2 km (2.61 mi) cable length, we decided to further our testing by introducing measurement interference and testing the limits of what we could read. To do this, we used an electric power drill connected to AC power. Running the drill next to our long spool of cable, we were able to take a successful measurement.

Observing the chart on our VWAnalyzer, we discovered that a noticeable amount of interference had been filtered out of our measurement by the VSPECT technology. If we had used other vibrating wire interfaces that are based on time-domain analysis, this interference would have caused a big problem!

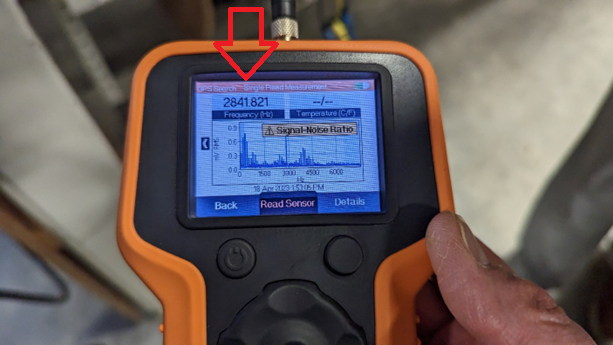

To create even more interference, we placed the drill next to the sensor itself and ran it while taking a measurement. The amount of interference we introduced was astronomical! The interference was so high that the VWAnalyzer alerted us that our Signal-Noise Ratio was very low. Despite this incredible amount of interference, you can see from the image below that the VWAnalyzer’s VSPECT technology still enabled us to take an accurate reading.

The Results

In summary, we successfully took an accurate vibrating wire measurement over a cable length of 4.2 km (2.61 mi) while introducing a significant amount of interference. Some of our customers also perform vibrating wire measurements over long cable lengths. In fact, some of them claim to conduct measurements over cable lengths of up to 9.66 km (6 mi)! While using long cable lengths for your vibrating wire measurements is not optimal, scenarios such as these attest to the superiority of our VSPECT technology.

For more information on VSPECT or help troubleshooting a vibrating wire application, read my previous blog article: “Troubleshooting Vibrating Wire Piezometers.”

If you have any questions or comments, please post them below.

Nathanael Wright is a Technical Support Engineer at Campbell Scientific, Inc. He provides technical support for data loggers, instruments, and communications equipment. Nathanael has a bachelor's degrees in Computer Information Science and Business Administration, and an MBA. In addition, Nathanael has more than 15 years of experience working in IP communications. Away from work, he enjoys breakdancing, hiking, writing, publishing books, and fiddling with computer equipment.

Nathanael Wright is a Technical Support Engineer at Campbell Scientific, Inc. He provides technical support for data loggers, instruments, and communications equipment. Nathanael has a bachelor's degrees in Computer Information Science and Business Administration, and an MBA. In addition, Nathanael has more than 15 years of experience working in IP communications. Away from work, he enjoys breakdancing, hiking, writing, publishing books, and fiddling with computer equipment.

Comentários

Please log in or register to comment.